Build Blog

Build Blog 1 – A diverse week!?

Build Blog 1! I’m absolutely not a writer so forgive me for any spelling mistakes but I’ll do my best to make this an interesting blog. It has been a busy and interesting week with all kinds of stuff happening which I will share in this blog.

4-Engine Modified

In the past weeks I have been collecting parts for this modified project. Which was not an easy task in times of Covid-19 due to many things not being in stock or having a lot of delays.

This build will have a set of four LRP ZR.32 Spec4 engines with rotostarts. It will have a lot of anodized blue accents on request of the customer, so blue air & fuel filters it is, as well as blue flywheels. If you follow us for a longer time you might recognize some parts… indeed! It’s the chassis and crossbox of the old Lambada tractor. This build will be based on the same concept with some small tweaks to make it suitable for the USA pulling style.

Soon, the engines will go through a break-in process so they are ready to deliver full power since the very first run. Once they are ready, everything will be build up and put together with paint and decals as well.So stay tuned for this build! It’s one of the projects I’m very excited about.

Below a few images of the digital render for this project and the initial set-up to get an idea of the full picture.

And as last, a picture of the original Lambada tractor which was owned by the Dutch Kiekuut team.

T-Maxx diff spool

In our new generation tractors, T-maxx axles will be used. Since most tractors in the US use a solid-axle rear end rather than a differential,

a spool has to be design to lock the axle.

This is the initial aluminum prototype, for now it will accept 6mm or 1/4″ sized axles. But later hopefully also 8mm and 3/8″ axles.

Custom tractor driveline

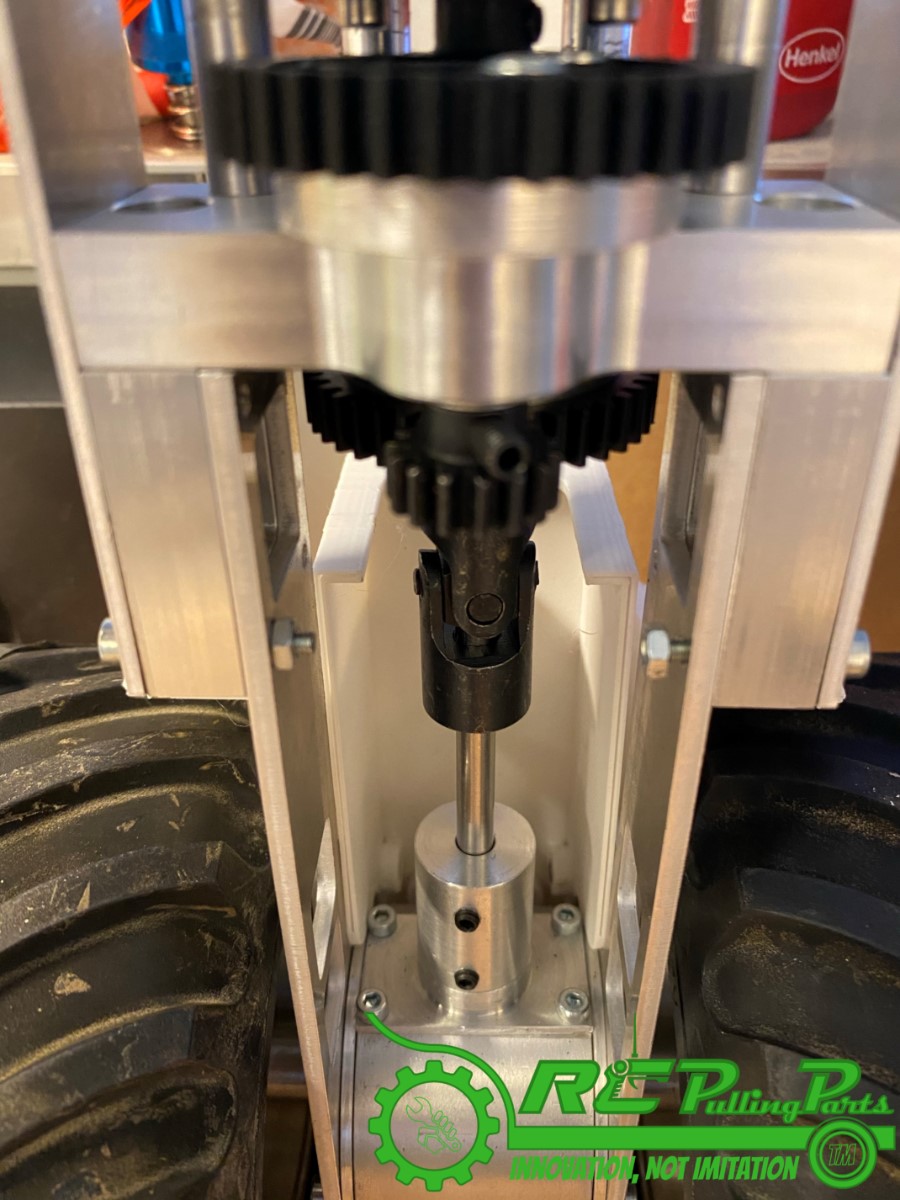

I’m working on this tractor for a while now, but thankfully it’s almost ready to go to the new owner! This week the driveline got the final assembly and was checked to make sure everything runs smoothly.

As you can see on the pictures, the gearbox is fully made of aluminum. It has a double drop gearing system with a 4600kv motor. All this is connected to a heavy-duty universal joint which connects it to a custom rear axle.

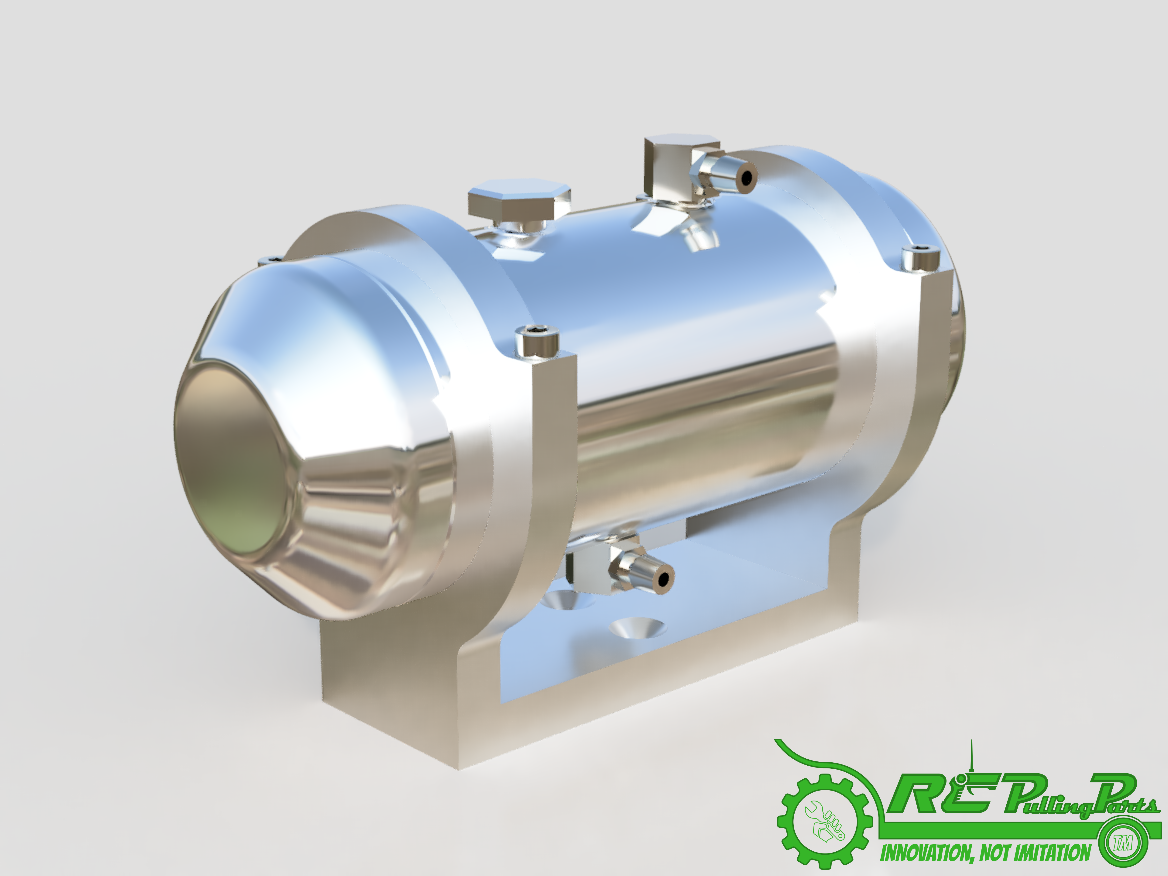

Custom aluminum fuel tank

Another project is a custom aluminum fuel tank for a nitro 4×4 truck. I made a 3d model for the tank, tweaked to the customers requirements. The tank section itself and the sidecaps are cnc machined so far.

While milling the mounts, the old cnc mill sadly died. Luckily we’re working on a brand new machine is being to be back in business ASAP.

Final word

That’s it for build blog 1! I enjoyed writing it and I hope you enjoyed reading it! Please let me know if you have any suggestions or requests for future build blogs.

On to the next one!